In today’s competitive business landscape, terms like “Lean Manufacturing,” “Six Sigma,” and “Continuous Improvement” are ubiquitous. However, many organizations invest millions in implementing these tools and methodologies, only to watch results stagnate and old habits creep back in. The core problem? They focus on the “how” (the tools) but ignore the “why” (the culture).

This is where the Shingo Model comes in. More than just a set of tools, it is a philosophical and predictive framework designed to guide a deep and sustainable cultural transformation. It even positions itself as a crucial mediating system that facilitates the transition from Industry 4.0 toward a human-centric Industry 5.0 (Qeytasi et al. 2025).

This article is a comprehensive guide where we will break down what the Shingo Model is, its fundamental principles, its structure, and why it represents the next evolutionary step for any organization seeking true Operational Excellence.

Key takeaways

- The Shingo Model is the cultural foundation (the “why”) that makes technical tools like Lean (the “how”) sustainable.

- Excellence is an indirect result; it is achieved by focusing on the Principles and Systems that drive ideal Behaviors, not by directly chasing results (KPIs).

- The model demands a socio-technical balance, prioritizing the “social subsystem” (people and culture) on the same level as the “technical subsystem” (tools and processes).

- Its 10 Guiding Principles are universal, applying successfully in any sector (not just manufacturing) and company size.

- Shingo is not a project, but a continuous and perpetual cultural transformation—a constant journey toward perfection and sustainability.

What exactly is the Shingo Model?

The Shingo Model is an organizational excellence framework developed by the Shingo Institute, part of the Jon M. Huntsman School of Business at Utah State University. It is not simply another improvement methodology but a comprehensive roadmap for building a culture of sustainable excellence.

In other words, while Lean and Six Sigma focus on the what and how (processes and tools), the Shingo Model delves into the why (principles and behaviors). As highlighted by Sá et al. (2022), this model addresses the strong connection between organizational culture, sustainability, and the overall performance of organizations in their pursuit of Sustainable Operational Excellence. This focus is especially relevant to culture- and leadership-related aspects (Tran, 2024).

Its fundamental purpose is to guide leaders in designing systems that drive ideal behaviors throughout the organization, thereby generating optimal and sustainable results.

Beyond tools: The focus on principles and behaviors

Most improvement initiatives fail because they focus exclusively on implementing Lean tools (like 5S, Kanban, or VSM) without changing the underlying mindset. Employees might use the tools out of obligation, but when pressure mounts, they revert to their old behaviors.

The Shingo Model argues that tools are just the tip of the iceberg. True excellence comes from aligning Guiding Principles (universal, timeless values) with Systems (how work is done) to drive ideal or specific Behaviors. These behaviors only emerge if they are anchored in guiding principles that people truly believe in and live by.

In short, the Shingo Model provides the “why” that gives meaning to the “how,” and it is based on a clear hierarchy: Principles $\rightarrow$ Behaviors $\rightarrow$ Systems $\rightarrow$ Results.

The origin: Who was Dr. Shigeo Shingo?

To understand the model, it is crucial to know its namesake, Dr. Shigeo Shingo (1909-1990). He was a Japanese mechanical engineer and one of the world’s leading experts on manufacturing processes, often recognized as a key architect of the Toyota Production System (TPS), although he was never a direct employee of Toyota.

Dr. Shingo was not just a theorist; he was a pragmatic implementer. His contributions revolutionized modern manufacturing:

- Poka-Yoke (Mistake-Proofing): He developed the concept of “Zero Quality Control,” creating simple mechanisms (Poka-Yoke) that make it impossible or immediately obvious to make an error, thus ensuring quality at the source.

- SMED (Single-Minute Exchange of Die): In the 1950s, while working at Mazda, he developed the SMED methodology, which seeks to dramatically reduce tool changeover times (from hours to minutes), enabling smaller production batches and more flexible flow.

The Shingo Institute adopted his name because his teachings focused on understanding the fundamental principles behind the success of the TPS, rather than just copying its tools.

The Shingo logic

The model is based on a powerful logical chain known as the “Three Insights of Organizational Excellence.” These insights explain the connection between culture, behavior, and results.

Ideal results require ideal behaviors

The first insight is a simple observation: what an organization achieves (its results) is a direct consequence of how its people act (their behaviors). If you want different or better results (e.g., zero defects, 100% on-time delivery), you need your staff to adopt specific, ideal behaviors that lead to those results.

Purpose and systems drive behavior

People do not behave in a certain way by chance. Human behavior in an organization is a direct response to the systems in which it operates. These systems include everything: how performance is measured, how people are rewarded, standard work processes, Human Resources (HR) policies, and the way leaders interact with their teams.

If a company’s systems (purpose) are poorly designed (e.g., rewarding quantity over quality), they will drive non-ideal behaviors (producing quickly, even with errors), no matter how many “Quality First” posters hang on the walls.

Principles inform ideal behavior

This is the key insight. If systems drive behavior, what should guide the design of those systems? The answer: Guiding Principles.

Principles are universal, timeless truths about the consequences of behavior. For example, the principle of “Respect Every Individual” informs a leader on how to design a suggestion system or a performance review process. Systems designed based on correct principles will naturally guide people toward ideal behaviors.

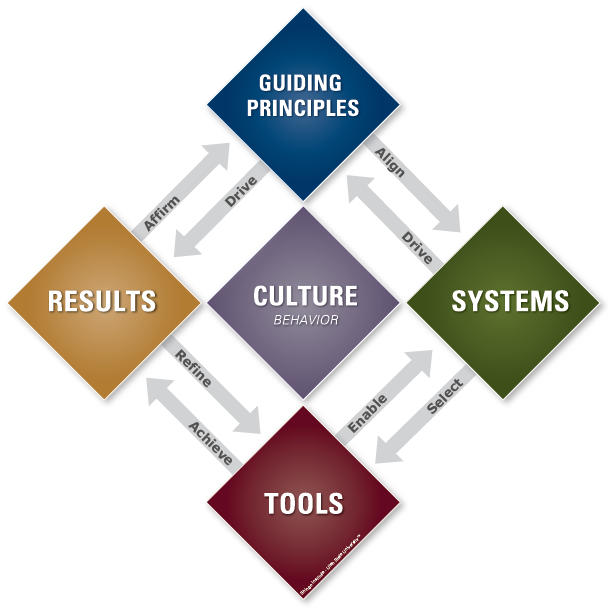

The Shingo Diamond Structure: Understanding the 5 key elements

The Shingo Model is visually represented by the “Shingo Diamond,” which illustrates the interrelationship between the five fundamental elements of excellence.

The center: Organizational culture

The central element of the model is Culture. This is not defined by official mission statements, but rather is the sum of the organization’s actual behaviors and unspoken assumptions. It is, in fact, the result of the interaction of all the other elements.

It is not possible to “implement” a culture; it can only be built by designing the right systems based on principles.

In this vein, Abraham (2025) concluded that within the Operational Excellence framework postulated by the Shingo Model, Employee Engagement is crucial. It plays a fundamental role in driving continuous improvement and aligning individual efforts with organizational goals, thus solidifying its role as a key human element for unified strategic action.

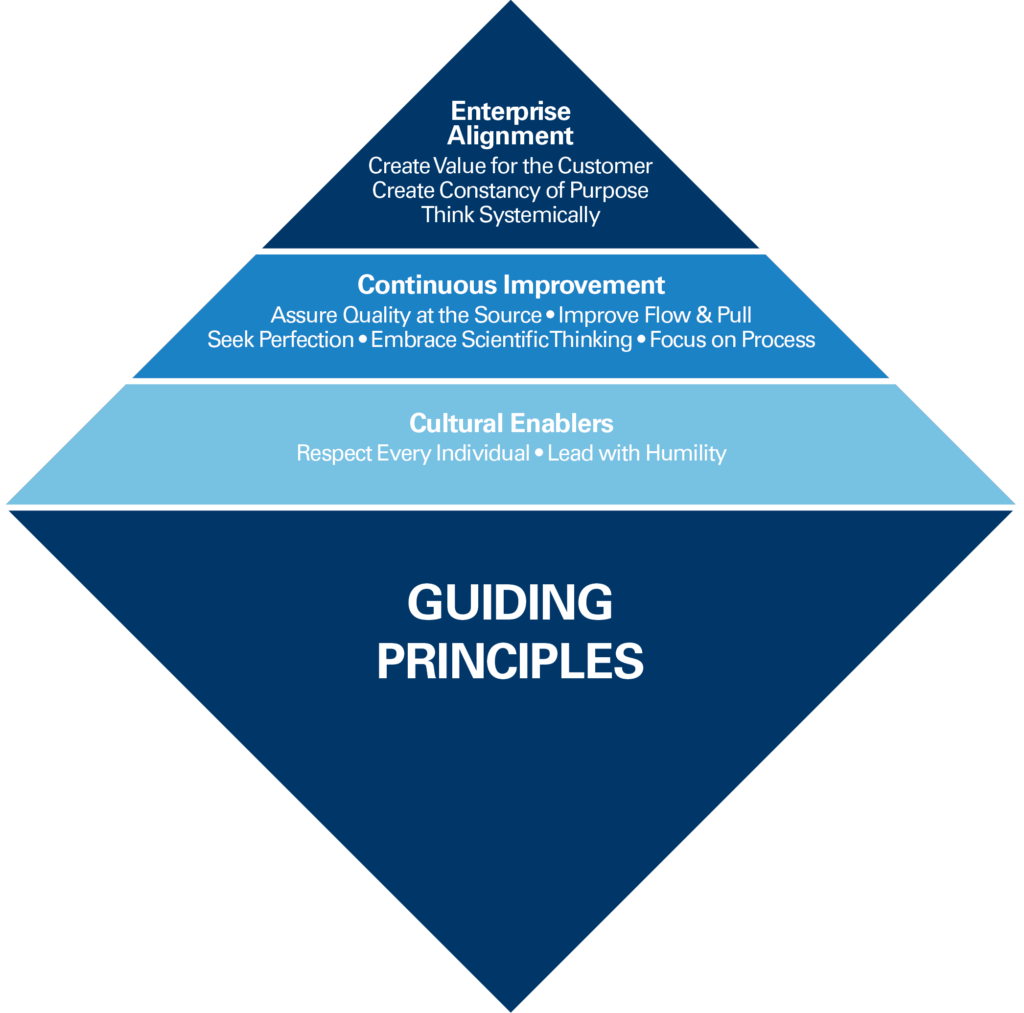

The Foundation: Guiding principles

These are the foundation upon which everything else is built. The model identifies 10 principles (which we will see in detail later) that are the key to sustainable excellence.

The Drivers: Systems and Tools

- Systems: These are the set of processes and mechanisms designed to achieve an objective (e.g., hiring system, maintenance system, quality system). Systems are the vehicle for operationalizing the principles.

- Tools: These are point solutions (like Poka-Yoke, SMED, 5S, Kanban). Tools are part of the systems, but they are not the system itself.

The Objective: Results

At the top of the diamond are the Results (KPIs). The model teaches that results are lagging indicators. If you focus only on manipulating results, you will fail. If you focus on perfecting the principles, systems, and behaviors (leading indicators), ideal results will follow as a consequence.

The 10 Guiding Principles of the Shingo Model

The 10 Guiding Principles are the core of the model. They are grouped into three dimensions that reflect the needs of any organization: people, processes, and purpose.

Dimension 1: Cultural Enablers (Focus on People)

This dimension is the foundation of cultural transformation. It recognizes that excellence can only be achieved through the engagement and potential of every person in the organization.

- Respect Every Individual: This goes beyond mere politeness. It means trusting people, developing their skills, and treating them as valued partners in improvement.

- Lead with Humility: This requires leaders to recognize they do not have all the answers. A humble leader listens, learns from others (especially frontline staff), and is willing to admit mistakes.

Dimension 2: Continuous Improvement (Focus on Processes)

This dimension centers on the relentless pursuit of better ways of working, based on observation and the scientific method.

- Seek Perfection: This is the mindset that there is always a better way. It fosters a constructive dissatisfaction with the status quo and a constant aspiration toward an ideal state.

- Embrace Scientific Thinking: This means using rigorous cycles of experimentation (like PDCA – Plan-Do-Check-Act) to test hypotheses, learn from failures, and make decisions based on data, not opinions.

- Focus on Process: Understanding that results are a consequence of processes. When a problem occurs, the question is not “Who made a mistake?” but “What failed in the process?”

- Assure Quality at the Source: Inspired by Shingo’s Poka-Yoke, this principle holds that quality must be built into the process. Every worker is responsible for the quality of their work and must not pass defects to the next step.

- Improve Flow & Pull: This seeks to create a continuous, uninterrupted flow of value toward the customer, eliminating waste and producing only what the customer demands (pull) when they demand it.

Dimension 3: Enterprise Alignment (Focus on Purpose)

This dimension ensures that the entire organization is pulling in the same direction, with a clear understanding of the mission and vision.

- Think Systemically: Understanding that the organization is a complex system of interconnected parts. A decision in one area (e.g., Purchasing) will have ripple effects in others (e.g., Production). It requires optimizing the whole, not just the parts.

- Create Constancy of Purpose: Defining and tirelessly communicating why the organization exists (its mission), where it is going (its vision), and how it will get there (its strategy).

- Create Value for the Customer: The starting point for all activity. Value is defined through the eyes of the customer: what they are willing to pay for. Everything else is, potentially, waste.

Table: The 10 Shingo Guiding Principles.

| Dimension | Guiding Principle | Primary Focus |

| Cultural Enablers | 1. Respect Every Individual | Recognize the inherent value and potential of every person. |

| 2. Lead with Humility | Be willing to listen, learn, and seek feedback. | |

| Continuous Improvement | 3. Seek Perfection | A constant aspiration for improvement; never be satisfied. |

| 4. Embrace Scientific Thinking | Use experimentation cycles (PDCA) to learn and improve. | |

| 5. Focus on Process | See that processes produce results; do not blame people. | |

| 6. Assure Quality at the Source | Detect and prevent errors where they occur; do not pass on defects. | |

| 7. Improve Flow & Pull | Maximize customer value by eliminating waste. | |

| Enterprise Alignment | 8. Think Systemically | Understand the interconnection of all processes and systems. |

| 9. Create Constancy of Purpose | Unwavering clarity on mission, vision, and strategy. | |

| 10. Create Value for the Customer | Define value from the customer’s perspective. |

Shingo Model vs. Lean and Six Sigma: What’s the Difference?

This is one of the most common points of confusion. The Shingo Model does not compete with Lean or Six Sigma; it complements them and gives them a sustainable foundation.

The “Why” (Shingo) vs. The “How” (Lean/Six Sigma)

- Lean and Six Sigma are methodologies rich in tools (“the how”). They provide a technical arsenal for solving problems: VSM for analyzing flow, 5S for organizing the workplace, DMAIC for reducing variation, and SMED for reducing setup times.

- The Shingo Model provides the cultural context (“the why”). It explains why those tools should be used. For example, you don’t do 5S just to have a clean workshop; you do it because you “Respect Every Individual” (giving them a dignified work environment) and seek to “Improve Flow” (making problems visible).

Without Shingo principles, Lean becomes “anorexic Lean”: a ruthless cost-cutting exercise that cuts staff, burns out employees, and destroys morale, making it completely unsustainable.

On another note, Carvalho et al. (2023) validated the usefulness of a conceptual model they developed, which integrates the requirements of ISO Management System Standards (MSS) with the guiding principles of the Shingo Model for Operational Excellence.

The Common Mistake: Partial Adoption of Tools

Studies on Lean implementation, particularly in the maquiladora (assembly) industry, show a worrying reality: a large majority of companies (over 50%) adopt practices partially. They focus on the technical tools (the “Technical System”) that are easy to implement, such as standard work or 5S.

However, they neglect the “Social System”: people development, humble leadership, and respect. This unbalanced adoption is the primary cause of failure. The Shingo Model corrects this by placing Cultural Enablers at the same level of importance as Continuous Improvement.

A Socio-Technical Framework: Balancing People and Processes

The Shingo Model aligns perfectly with Socio-Technical Systems (STS) Theory. This theory, developed in the 1950s, posits that any organization is a combination of two subsystems:

- The Technical Subsystem: The tools, technology, processes (the focus of Lean).

- The Social Subsystem: The people, their relationships, skills, and culture (the focus of Shingo).

STS demonstrates that optimizing only one system at the expense of the other (like implementing technical tools while ignoring people) will always lead to suboptimal results. The Shingo Model is the clearest framework for achieving this socio-technical balance.

Practical Application: How is the Shingo Model Implemented?

The Shingo Model is not a program that is “installed” in 90 days. It is a continuous transformation that is learned and lived. The Shingo Institute offers a learning path through its workshop series.

The Shingo Workshop Series

Shingo workshops are designed to help leaders internalize the principles and redesign their systems; according to Plenert (2017), the workshops are as follows:

- DISCOVER EXCELLENCE (Prerequisite): The fundamental introduction to the model, the 3 Insights, and the 10 Principles.

- CULTURAL ENABLERS: A 2-day workshop that takes participants deeper into the Shingo Model by focusing on the principles identified in the Cultural Enablers dimension: Respect Every Individual and Lead with Humility.

- CONTINUOUS IMPROVEMENT: A three-day workshop. It begins by teaching participants how to clearly define value through the eyes of their customers and takes them deeper into the Shingo Model by focusing on the principles identified in the Continuous Improvement dimension: Seek Perfection, Embrace Scientific Thinking, Focus on Process, Assure Quality at the Source, and Flow & Pull Value.

- ENTERPRISE ALIGNMENT and RESULTS: A two-day workshop. It focuses on the principles identified in the Enterprise Alignment and Results dimensions: Think Systemically, Create Constancy of Purpose, and Create Value for the Customer.

- BUILD EXCELLENCE: The final workshop, which consolidates all the knowledge for leading the transformation, lasts two days. In this workshop, participants will: Design or create a system, Answer the question: “How do I get everyone engaged?”, Build upon the principles of business excellence, Understand the relationship between behaviors, systems, principles, and how they drive results, and Learn how Key Behavior Indicators (KBIs) drive Key Performance Indicators (KPIs), and how this leads to excellent results.

Schein’s Model of Culture: Understanding Tacit Assumptions

To apply the model, leaders must be able to see their own culture. Edgar Schein’s model of culture is fundamental here. Schein describes culture at three levels:

- Artifacts: What you see (logos, dress code, tools used). This is the most superficial level.

- Espoused Values: What the company says it values (the mission statement on the wall).

- Tacit Assumptions: The deeply ingrained, unconscious beliefs that truly drive behavior.

The Shingo Model forces leaders to confront their tacit assumptions. If a leader says they “respect every individual” (espoused value), but their tacit assumption is “workers only do what they are paid for,” their systems will reflect control and mistrust, and the transformation will fail. In this regard, Hines et al. (2025) suggest an extension of the Shingo Model to incorporate the human-centric aspects of Lean leadership. Meanwhile, the study by Snyder et al. (2024) contributed to a deeper understanding of how to develop values-based leadership using the Shingo Model, given the strong link the model demonstrates between organizational culture and business excellence.

Examples of Shingo Model Implementation

Manufacturing

A relevant instrumental and longitudinal case study, documented by Kelly and Hines (2018), was conducted at the Abbott Diagnostics manufacturing facility in Longford, Ireland. The research focuses on two key points: first, the demonstration of a successful and sustainable implementation of the Shingo approach; and second, the lessons learned regarding knowledge transfer across multiple sites.

Hospital Waste Management

The integration of the Shingo Model with simulation has been proposed by Ferreira et al. (2025) as a key strategy for achieving operational excellence, being particularly relevant in hospital waste supply chains. The application of this combined methodology allows organizations to foster a culture of continuous improvement, effectively identify waste, and raise quality at all stages of the process, from collection to final disposal.

Conclusion: Why the Shingo Model is Key to Sustainable Results

The Shingo Model does not offer a quick fix or a magic tool. It offers something far more powerful: a sustainable path to excellence based on truth. In this respect, Sá et al. (2023) conclude that the Shingo model guides organizations toward achieving sustainable economic, social, and environmental results.

Shingo teaches us that tools are necessary but insufficient. It reminds us that organizations are human systems, not just machines. And it provides us with a common language (the 10 Principles) to design systems that bring out the best in everyone.

If your organization is tired of improvement programs that fade away and is seeking a real transformation that endures, the Shingo Model is not just an option; it is the logical next step on the journey toward sustainable operational excellence.

Frequently Asked Questions (FAQ) about the Shingo Model

Does the Shingo Model replace Lean?

No. The Shingo Model does not replace Lean or Six Sigma. Rather, it acts as the underlying cultural operating system that allows Lean and Six Sigma tools to work effectively and sustainably. It provides the cultural “why” for the technical “how” of Lean.

How long does it take to implement the Shingo Model?

There is no fixed timeline. The Shingo Model is not a project with a start and end date; it is a perpetual cultural transformation. It is a “seek perfection” journey that never ends. Initial results can be seen in months, but embedding the principles into the culture takes years of constant effort.

Is the Shingo Model only for manufacturing?

Absolutely not. Although its roots are in manufacturing (through Dr. Shingo and the TPS), the 10 Guiding Principles are universal. The model is successfully applied in sectors as diverse as healthcare (hospitals), financial services, logistics, government, and even education.

Is my company too small for the Shingo Model?

Absolutely not. The principles (Respect, Humility, Customer Focus, Process Focus) are universal. In fact, it is sometimes easier for an agile SME with a committed owner to adopt this culture than for a corporate giant full of silos.

What is the difference between the Shingo Model and the Baldrige Model?

Both are excellence frameworks, but they have different approaches. The Baldrige Model is a prescriptive evaluation framework that defines what an organization must do in seven categories (Leadership, Strategy, Customers, etc.) to be excellent. It is an excellent diagnostic tool.

The Shingo Model is a predictive, principles-based framework. It focuses on the why and the causal connection: Principles -> Systems -> Behaviors -> Results. It is less prescriptive about categories and more profound regarding philosophy and culture. Many organizations use Baldrige to identify gaps and Shingo to close them culturally.

References

Abraham, S. (2025). Driving Operational Excellence through Engagement: A Study on Cultural Enablers, Process Improvement, and Strategic Alignment. In International Operations Management Conference on Reengineering Business Ecosystems: Synergies and Innovations in Operations and Beyond. Shri Dharmasthala Manjunatheshwara Institute for Management Development, Mysuru, India. 9 p.

Carvalho, M., Sá, J. C., Marques, P. A., Santos, G., & Pereira, A. M. (2023). Development of a conceptual model integrating management systems and the Shingo Model towards operational excellence. Total Quality Management & Business Excellence, 34(3-4), 397-420.

Ferreira, A., Ramos, A.L., Ferreira, J.V., Ferreira, L.P. (2025). From Waste to Operational Excellence Through Simulation Techniques in the Hospital Waste Supply Chains. In: Moldovan, L., Gligor, A. (eds) The 18th International Conference Interdisciplinarity in Engineering. Inter-Eng 2024. Lecture Notes in Networks and Systems, vol 1249. Springer, Cham. https://doi.org/10.1007/978-3-031-81685-7_16

Hines P, Zak H, Salvadorinho J (2025), “The human face of lean: expanding the Shingo model through leadership behaviours“. International Journal of Lean Six Sigma, Vol. ahead-of-print No. ahead-of-print. https://doi.org/10.1108/IJLSS-06-2025-0151

Kelly, S., & Hines, P. (2018). Discreetly embedding the Shingo principles of enterprise excellence at Abbott Diagnostics manufacturing facility in Longford Ireland. Total Quality Management & Business Excellence, 30(11–12), 1235–1256. https://doi.org/10.1080/14783363.2017.1363645

Plenert, G. J. (Ed.). (2017). Discover excellence: an overview of the Shingo model and its guiding principles.

Qeytasi M, Enayati Bidgoli A, Habibi M, Tortorella GL (2025), “Toward a human-centric digital workplace: a Shingo-based framework bridging Industry 4.0 and 5.0“. International Journal of Lean Six Sigma, Vol. ahead-of-print No. ahead-of-print. https://doi.org/10.1108/IJLSS-05-2025-0112

Sá, J. C., Reis, M., Dinis-Carvalho, J., Silva, F. J. G., Santos, G., Ferreira, L. P., & Lima, V. (2022). The Development of an Excellence Model Integrating the Shingo Model and Sustainability. Sustainability, 14(15), 9472. https://doi.org/10.3390/su14159472

Sá, J. C., Oliveira, A. R. ., Carvalho, J. D., Santos, G., & Silva, F. (2023). A New Conceptual Model for Excellence in Business Towards Sustainable Development. Quality Innovation Prosperity, 27(2), 33–60. https://doi.org/10.12776/qip.v27i2.1866

Snyder, K., Ingelsson, P., & Bäckström, I. (2024). Developing value-based leadership for sustainable quality development: a meta-analysis from a study of Lean manufacturing. International Journal of Lean Six Sigma, 15(6), 1245-1264.

Tran, C. (2024). Building an Operational Excellence Program (Doctoral dissertation, Auburn University). 17 p.

Editor and founder of “Innovar o Morir” (‘Innovate or Die’). Milthon holds a Master’s degree in Science and Innovation Management from the Polytechnic University of Valencia, with postgraduate diplomas in Business Innovation (UPV) and Market-Oriented Innovation Management (UPCH-Universitat Leipzig). He has practical experience in innovation management, having led the Fisheries Innovation Unit of the National Program for Innovation in Fisheries and Aquaculture (PNIPA) and worked as a consultant on open innovation diagnostics and technology watch. He firmly believes in the power of innovation and creativity as drivers of change and development.