Have you ever wondered how collaboration between businesses can drive sustainability and economic growth?

Various international agreements have been contributing to raising awareness about climate change issues and the pursuit of sustainable solutions. Within this framework, “Industrial Symbiosis” emerges as a powerful strategy that is revolutionizing the way companies operate and thrive.

Industrial Symbiosis (IS) is a collaborative environmental action in which companies share or exchange by-products, materials, energy, or waste as a way to economically reduce the cumulative environmental impact (Walls and Paquin, 2015).

In this article, we will delve into the concept of industrial symbiosis, its benefits, notable examples, and its crucial role in the circular economy.

What is Industrial Symbiosis?

Industrial symbiosis is a term that is gaining increasing relevance in the conversation about sustainability and the circular economy. This strategy focuses on collaboration and the coexistence of different companies and industrial sectors to harness resources, reduce waste, and minimize environmental impact.

The most widely accepted definition of IS is the one published by Karenborg Company in Denmark, which states: “Industrial symbiosis refers to the joint improvement of survival and profitability through cooperation between different companies, while simultaneously achieving resource conservation and environmental protection through this consensus” (Mallawaarachchi et al., 2020).

Meanwhile, Lawal et al. (2021) define IS as a mutually beneficial collaboration between two or more industries or entities to exchange resources, with the potential to generate economic, social, and environmental benefits and support sustainable development (Huang et al., 2019).

In other words, IS allows entities and companies, which are traditionally separate, to cooperate in sharing resources, contributing to increased sustainability, and reaping economic and social benefits (Neves et al., 2022).

Benefits of Industrial Symbiosis

Neves et al. (2022) highlight that the application of the industrial symbiosis approach has enormous potential, and although it has primarily focused on the manufacturing industry, the possibilities for applying IS go beyond that. In this regard, here are some benefits:

Waste reduction

Industrial symbiosis reduces waste generation, benefiting the environment and reducing the costs associated with waste disposal. Research results by Martin and Harris (2018) suggest that an IS network has the potential to make a positive contribution to the environmental performance of industries and the socioeconomic status of the region.

Energy efficiency

By sharing resources and energy, companies can reduce their energy consumption and, as a result, decrease their carbon footprint. Chen et al. (2022) report that in an eco-industrial park in China, energy use efficiency increased by 0.38 times.

Promotion of the circular economy

IS is a key component of the circular economy, where products and materials are efficiently recycled, reused, and remanufactured. Demartini et al. (2019) suggest it as a potential business model that encourages companies to transition from linear production to circular.

Moreover, Yu et al. (2015) recommend that government actions in the development of IS include stringent environmental standards, comprehensive resource utilization schemes, financial support, circular economy, and guidance for eco-industrial park planning.

Why is IS crucial for the circular economy?

In the context of the circular economy, where reduction, reuse, and recycling are fundamental, IS plays an essential role because it helps close the loops of materials and resources, reducing the need to extract and produce new resources. This has a significant impact on nature conservation and biodiversity preservation.

Mortensen and Kørnøv (2019) emphasize that IS is a strategic tool for implementing the circular economy, and Abreu and Ceglia (2018) recognize it as a useful strategy to support the transition from a linear to a circular economy.

Similarly, Herczeg et al. (2018) report that IS pursues a vision of an industrial ecosystem in which companies from different industries form a collaborative supply network based on local recycling of industrial waste, byproducts, and surplus services.

The concept of industrial symbiosis has emerged as a strategy for utilizing waste in a production chain, based on the physical exchange of waste and materials, which paves the way for one company’s waste to become another’s input, all underpinned by business collaboration (Cárcamo and Peñabaena-Niebles, 2022).

Industrial Ecology and Industrial Symbiosis: a harmonious partnership

Industrial ecology is closely related to industrial symbiosis as it focuses on studying industrial systems as complex networks. The concept of IS has emerged under the umbrella of Industrial Ecology (IE), ensuring a reduction in environmental deprivation through the efficient use of waste and by-products (Mallawaarachchi et al., 2020).

According to Lawal et al. (2021), sustainability and industrial ecology are the key drivers of industrial symbiosis and eco-industrial parks. Additionally, industrial symbiosis is considered one of the most effective solutions for reducing the impact of waste emissions and a key driver for transitioning towards sustainable production models (Yazan et al., 2016).

The principles of industrial ecology, such as material flow analysis and life cycle assessment, are often applied to enhance industrial symbiosis practices. This harmonious partnership results in a more sustainable and efficient industrial landscape.

Industrial Symbiosis: inspiring examples

Worldwide, there are numerous examples of synergistic IS networks reported in the literature, varying in terms of the number of participants, types of economic activities, and how they are organized (Neves et al., 2019). Here are some of them:

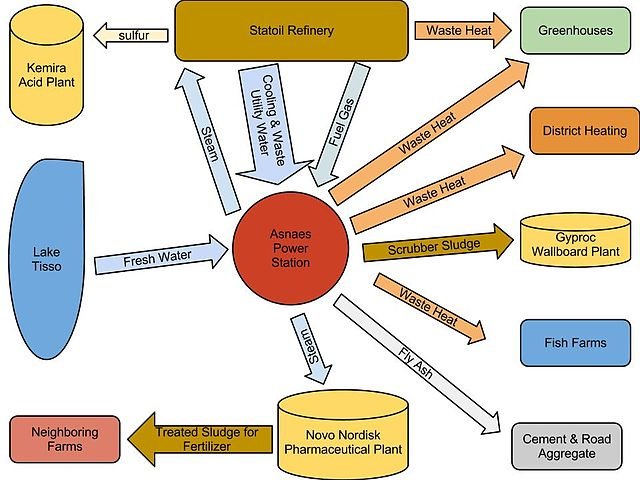

Kalundborg Eco-Industrial Park, Denmark

This is a classic example of industrial symbiosis. Companies in the park share residual hot water, synthesis gas, and other by-products to reduce waste and improve energy efficiency.

As reported by Jacobsen (2006), all industries in symbiosis reduced their use of over 30 million m3 of groundwater, and in the period from 1990 to 2002, due to industrial symbiosis between the power plant and the refinery, over 7.6 million m3 of surface water was saved.

Chopra and Khanna (2014) emphasize that the success of Industrial Symbiosis (IS) in Kalundborg creates a network of waste, water, and energy exchange among companies based on contractual dependency.

Rizhao Economic and Technology Development Area (REDA)

Yu et al. (2015) investigated the evolution of industrial symbiosis and the development of eco-industrial parks, summarizing the drivers and characteristics of industrial symbiosis development in China. They highlight that REDA has 31 instances of industrial symbiosis involving businesses dealing with grain and food oil, as well as machinery.

The results show the environmental benefits of IS performances in 2011, and argue that the economic benefits were mainly the result of stricter environmental standards and fiscal preferences.

Urban Industrial Park in Guiyang, China

The implementation of this IS park led to a reduction of 1,090,000 tons of CO2 emissions per year.

Conclusion

Industrial symbiosis is a transformative approach that is changing how businesses operate toward a more sustainable future. By collaborating, sharing resources, and embracing the circular economy, companies can reduce their environmental impact and, at the same time, strengthen their businesses.

IS is a path to a greener and more prosperous world, and a recent focus is collaboration with various entities in the business environment. As highlighted by Neves et al. (2019), the strengthening of industrial symbiosis relationships is based not only on economic benefits but also on social and environmental benefits.

We hope this article has clarified your questions about “Industrial Symbiosis,” its benefits, and its relevance in the circular economy. If you’d like more information on specific examples or implementation strategies, don’t hesitate to explore our blog or get in touch with us. Sustainability is the path to the future, and industrial symbiosis is one of the keys to getting there.

References

Cárcamo, E. A. B., & Peñabaena-Niebles, R. (2022). Opportunities and challenges for the waste management in emerging and frontier countries through industrial symbiosis. Journal of Cleaner Production, 363, 132607.

Chen, X., Dong, M., Zhang, L., Luan, X., Cui, X., & Cui, Z. (2022). Comprehensive evaluation of environmental and economic benefits of industrial symbiosis in industrial parks. Journal of Cleaner Production, 354, 131635.

Chopra, S. S., & Khanna, V. (2014). Understanding resilience in industrial symbiosis networks: Insights from network analysis. Journal of environmental management, 141, 86-94.

de Abreu, M. C. S., & Ceglia, D. (2018). On the implementation of a circular economy: The role of institutional capacity-building through industrial symbiosis. Resources, conservation and recycling, 138, 99-109.

Demartini, M., Tonelli, F., & Govindan, K. (2022). An investigation into modelling approaches for industrial symbiosis: A literature review and research agenda. Cleaner Logistics and Supply Chain, 3, 100020.

Herczeg, G., Akkerman, R., & Hauschild, M. Z. (2018). Supply chain collaboration in industrial symbiosis networks. Journal of cleaner production, 171, 1058-1067.

Huang, M., Wang, Z., & Chen, T. (2019). Analysis on the theory and practice of industrial symbiosis based on bibliometrics and social network analysis. Journal of cleaner production, 213, 956-967.

Lawal, M., Alwi, S. R. W., Manan, Z. A., & Ho, W. S. (2021). Industrial symbiosis tools—A review. Journal of Cleaner Production, 280, 124327.

Mallawaarachchi, H., Sandanayake, Y., Karunasena, G., & Liu, C. (2020). Unveiling the conceptual development of industrial symbiosis: Bibliometric analysis. Journal of Cleaner Production, 258, 120618.

Martin, M., & Harris, S. (2018). Prospecting the sustainability implications of an emerging industrial symbiosis network. Resources, Conservation and Recycling, 138, 246-256.

Mortensen, L., & Kørnøv, L. (2019). Critical factors for industrial symbiosis emergence process. Journal of cleaner production, 212, 56-69.

Neves, A.; Godina, R.; G. Azevedo, S.; Pimentel, C.; C.O. Matias, J. The Potential of Industrial Symbiosis: Case Analysis and Main Drivers and Barriers to Its Implementation. Sustainability 2019, 11, 7095. https://doi.org/10.3390/su11247095

Neves, A., Godina, R., Azevedo, S. G., & Matias, J. C. (2020). A comprehensive review of industrial symbiosis. Journal of cleaner production, 247, 119113.

Walls, J. L., & Paquin, R. L. (2015). Organizational Perspectives of Industrial Symbiosis: A Review and Synthesis. Organization & Environment, 28(1), 32–53. https://doi.org/10.1177/1086026615575333

Yazan, D. M., Romano, V. A., & Albino, V. (2016). The design of industrial symbiosis: an input–output approach. Journal of cleaner production, 129, 537-547.

Yu, F., Han, F., & Cui, Z. (2015). Evolution of industrial symbiosis in an eco-industrial park in China. Journal of Cleaner Production, 87, 339-347.

Editor and founder of “Innovar o Morir” (‘Innovate or Die’). Milthon holds a Master’s degree in Science and Innovation Management from the Polytechnic University of Valencia, with postgraduate diplomas in Business Innovation (UPV) and Market-Oriented Innovation Management (UPCH-Universitat Leipzig). He has practical experience in innovation management, having led the Fisheries Innovation Unit of the National Program for Innovation in Fisheries and Aquaculture (PNIPA) and worked as a consultant on open innovation diagnostics and technology watch. He firmly believes in the power of innovation and creativity as drivers of change and development.