Scientists from Nanyang Technological University (NTU) in Singapore, with the support of the Japan Science and Technology Agency (JST), have built the world’s first automated “assembly line” for cyborg-insects. This prototype robotic system automates the delicate task of attaching miniature electronic backpacks to Madagascar hissing cockroaches, turning them into insect-computer hybrid robots.

This breakthrough overcomes one of the biggest obstacles to their practical use: mass production. By drastically reducing preparation time and human error, this milestone marks a decisive step toward the large-scale deployment of these agents in real-world scenarios.

The challenge: From manual surgery to precision assembly

Until now, creating a cyborg-insect was a slow and delicate manual process. A skilled technician had to manually implant electrodes into specific parts of the insect’s nervous system, a procedure that could take about 15 minutes and whose success was highly dependent on their skill. The fragility of the insect’s anatomy made the process difficult to scale for applications requiring hundreds or thousands of units, such as search and rescue after a disaster.

To overcome this challenge, the research team, led by Professor Hirotaka Sato of the NTU School of Mechanical and Aerospace Engineering, focused on two key innovations: a new motion control method and a fully automated assembly system.

A new way to “Drive” an insect

Instead of using the fragile antennae, scientists identified a much more robust and effective stimulation point: the intersegmental membrane located between the pronotum (the dorsal “shield” behind the head) and the mesothorax of the Madagascar hissing cockroach.

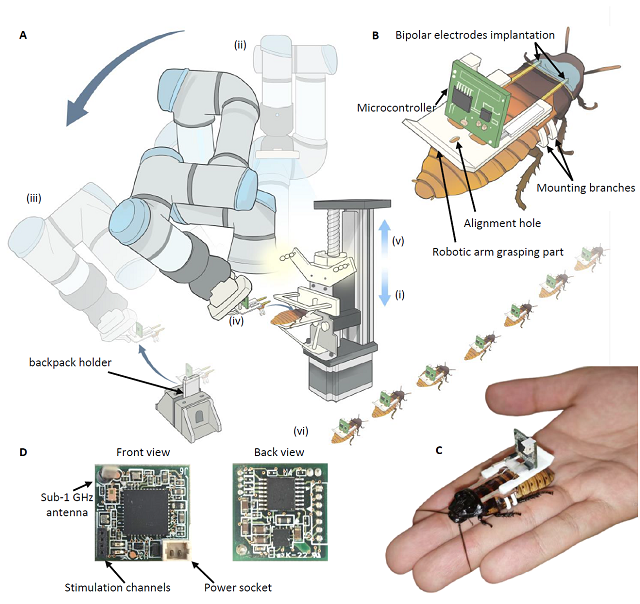

They designed a new generation of custom bipolar electrodes, manufactured using multi-material 3D printing and a metallization process. These electrodes, equipped with microneedles and an anchoring hook, not only ensure a secure implantation but are also more efficient. The stimulation protocol requires 25% less voltage than previous methods, which increases energy efficiency and extends operational time.

By applying a voltage of just 3.0 V, the researchers achieved precise control. Unilateral stimulation causes sharp turns of more than 70 degrees, while simultaneous stimulation on both sides achieves, for the first time, controlled deceleration, reducing the cockroach’s speed by 68.2%.

The assembly line: How a cyborg-insect is created in 68 seconds

The heart of this project is the automated assembly system, which integrates a robotic arm, computer vision, and a custom-made fixation structure. The process is a choreography of precision:

- Fixation and preparation: An anesthetized cockroach is placed in a structure that precisely exposes the intersegmental membrane.

- Computer vision: A high-resolution camera captures an image of the insect. An artificial intelligence model (TransUNet), enabled by a proprietary algorithm, analyzes the image and identifies the optimal anatomical point for electrode implantation.

- Robotic assembly: A UR3e robotic arm, guided by artificial vision, picks up the electronic “backpack” and, in a single motion, implants the electrodes and attaches it to the insect’s body.

The complete system can assemble a cyborg-insect in just 68 seconds. This is approximately 60 times faster than the traditional manual process. When processing four insects, the system completed all assemblies in less than 8 minutes, about 30 times faster than a human operator.

“Our innovation makes the dream of deploying a large number of cyborg-insects in real-life scenarios much more practical,” stated Professor Sato. “By automating the process, we can produce insect-computer hybrid robots quickly and consistently. This will be critical in urgent operations like search and rescue after a disaster.”

Once the insects are no longer on a mission, the electronic backpacks can be safely removed without adverse effects.

Real-world results: From the lab to the field

The system’s effectiveness was not only tested in the laboratory—where one robot was able to follow an “S”-shaped path and a swarm of four cyborg-insects covered more than 80% of an obstacle-filled area in just over 10 minutes—but it has also been validated in a real operation.

Baptism by fire in a humanitarian mission

On March 30, 2025, a team of 10 cyborg-insects was deployed in Myanmar with the Singapore Civil Defence Force (SCDF) as part of their Operation Lionheart contingent. The humanitarian aid mission was in response to a devastating 7.7 magnitude earthquake.

This deployment marked the first time cyborg-insects were used in a humanitarian operation, demonstrating their potential to locate survivors in disaster zones where conventional robots would struggle with access and battery life.

“With what we’ve learned from our field deployment, it is now essential to create an infrastructure that supports mass production and deployment,” noted Professor Sato. “Our assembly line is the first step toward that goal.”

Looking to the future, the team aims to improve the assembly system and integrate more complex sensors, such as thermal cameras or microphones, into the backpacks to detect human signals. The research, supported by JST’s Moonshot R&D Program, lays the foundation for a future where swarms of these biobots can be rapidly assembled and deployed where they are needed most.

Contact

Hirotaka Sato

School of Mechanical & Aerospace Engineering, Nanyang Technological University

Singapore

Email: hirosato@ntu.edu.sg

Reference (open access)

Lin, Q., Vuong, N., Song, K. et al. Cyborg insect factory: automatic assembly for insect-computer hybrid robot via vision-guided robotic arm manipulation of custom bipolar electrodes. Nat Commun 16, 6073 (2025). https://doi.org/10.1038/s41467-025-60779-1

Editor and founder of “Innovar o Morir” (‘Innovate or Die’). Milthon holds a Master’s degree in Science and Innovation Management from the Polytechnic University of Valencia, with postgraduate diplomas in Business Innovation (UPV) and Market-Oriented Innovation Management (UPCH-Universitat Leipzig). He has practical experience in innovation management, having led the Fisheries Innovation Unit of the National Program for Innovation in Fisheries and Aquaculture (PNIPA) and worked as a consultant on open innovation diagnostics and technology watch. He firmly believes in the power of innovation and creativity as drivers of change and development.